Automated Tube Decapper

The Hidden Costs & Risks of Manual Tube Decapping

Operational Challenges:

- Speed Bottlenecks

- Manual decapping slows processing by 15-30 seconds per tube

- Creates backlog during peak volumes (e.g., morning rounds)

- Repetitive Strain Injuries

- Staff perform 500+ twists/day → increased carpal tunnel claims (15-20% higher in manual labs)

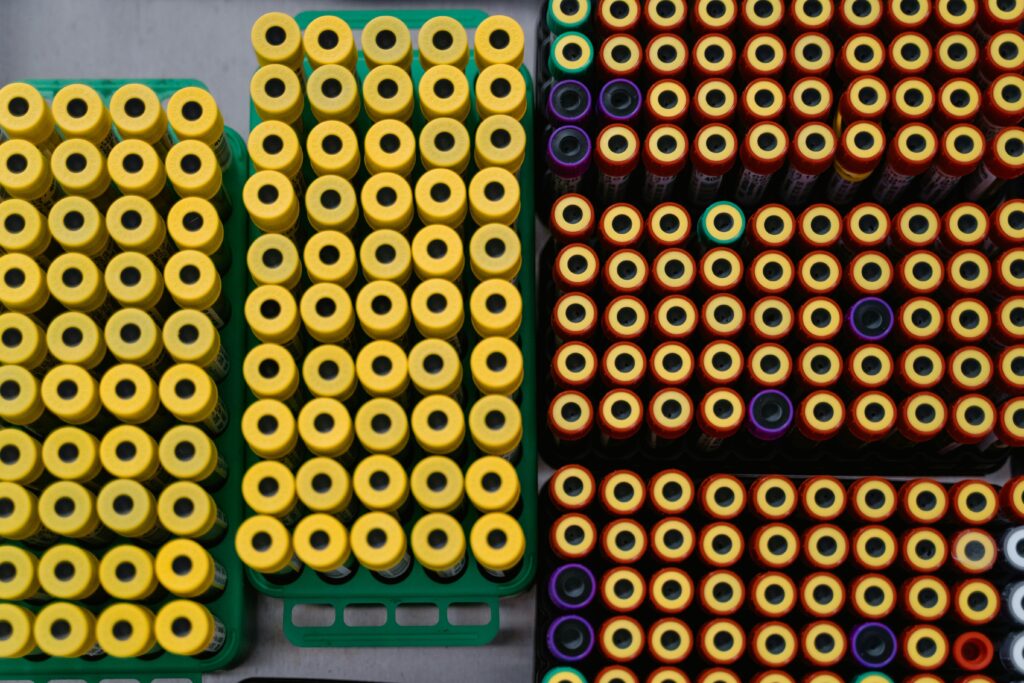

- Cross-Contamination Risks

- Aerosols from manual opening expose staff to biohazards (TB, hepatitis, etc.)

- Specimen Integrity Issues (Pre-Analytical Errors)

- Improper decapping can hemolyze samples (5-8% rejection rates)

- Caps dropped/lost → evaporation or contamination

- Tracking Gaps (Pre-Analytical Errors)

- No digital record of when/who opened each tube

- Labor Waste (Financial Impacts)

- Requires 1-2 dedicated FTEs per shift in core labs

- 20% slower TAT delays revenue cycles

Automated Decapping:

The Precision Solution

Seamless Integration:

✔ High-Throughput Processing – Decaps 600+ tubes/hour vs. 200 manually

✔ Zero Human Contact – Closed-system eliminates biohazard exposure

✔ Barcode Tracking – Logs exact decap time/staff for full audit trails

Tangible Outcomes:

◼ 100% compliance with OSHA/ISO 15189 biosafety standards

◼ 50-70% faster pre-analytical processing

◼ 30% reduction in sample rejections (hemolysis/clotting)

◼ $85K/year savings (1.5 FTE reallocation + reduced workers’ comp)

Discover Innovative Automation

This section describes the key features briefly.

Seamless Integration

Effortlessly connects with existing lab systems.

Enhanced Safety

Reduces contamination through automated handling.

Time Efficiency

Speeds up sample processing for busy labs.

User-Friendly Design

Intuitive interface simplifies operation and training.

Enhancing Laboratory Workflow with Precision Automation

Explore how the Automated Tube Decapper transforms lab efficiency by addressing key operational challenges.

Reduce Manual Handling Errors

Our system automates tube decapping, significantly lowering the risk of contamination and human error.

Save Time in High-Volume Labs

Designed for busy clinical settings, it speeds up sample processing and frees up valuable staff time.

Seamless Integration and Safety

Easily integrates into existing workflows, promoting a safer environment for laboratory personnel.

Customer Testimonials

Discover how our Automated Tube Decapper has transformed lab workflows through client success stories and feedback.

“The Automated Tube Decapper has significantly boosted our lab’s efficiency while ensuring safety standards remain top-notch.”

Dr. Emily Chen

Laboratory Director

“The seamless integration and ease of use truly improved our sample processing times beyond expectations.”

Michael Thompson

Clinical Lab Manager

“RayStar HEALTH’s solution demonstrates outstanding reliability and precision, enhancing our daily operations.”

Samantha Lee

Pathology Supervisor

“We are thoroughly pleased with the product’s performance and the professional support from the team.”

David Patel

Hospital Lab Technician

Enhance Laboratory Safety and Efficiency Now

Subscribe for updates and discover innovations that transform lab workflows.

- Automated Tube Decapping Precision

- Seamless Integration with Lab Systems

- Reduced Contamination Risks

- Time-Saving Automated Workflow

- User-Friendly Operation and Maintenance