Automated Tube Sealer

The Critical Need for Automated Tube Resealing in Modern Labs

Problems with Manual or Improper Resealing

1. Sample Integrity Risks

- Evaporation alters analyte concentrations (e.g., ethanol, volatile drugs)

- Exposure to air causes pH shifts in blood gas samples

- Increased risk of contamination from environmental particulates

2. Storage & Retest Challenges

- Manual Parafilm/capping fails 12-18% of the time during freezer storage

- No consistent seal pressure → sample degradation during long-term archiving

3. Workplace Hazards

- Staff injuries from repetitive hand-sealing motions (300+ tubes/day)

- Biohazard exposure when handling uncapped retain tubes

4. Compliance Gaps

- No audit trail for reseal times/staff (violates 21 CFR Part 11 requirements)

- Inconsistent seals fail accreditation inspections (CAP/CLIA)

5. Wasted Resources

- 8-10% of manually resealed samples become unusable for add-on tests

- Labor costs for dedicated staff to handle resealing workflows

Automated Resealing:

The Quality Control Solution

Precision Advantages:

✔ Gas-Tight Seals – Maintains CO2/O2 levels for blood gas stability

✔ Barcode-Linked Tracking – Documents exact reseal time/operator

✔ High-Throughput – Processes 500+ tubes/hour with zero fatigue

Measurable Benefits:

→ 42% reduction in sample rejection for add-on testing

→ Eliminates 1.0 FTE of manual labor per shift

→ 100% compliance with FDA/ISO storage requirements

→ 23% longer sample stability for toxicology/endocrine tests

Key Decision Factors:

◼ Integration: Works with major LIS and existing tube types?

◼ Footprint: Fits in existing post-analytical workflows?

◼ ROI: 9-14 month payback period typical?

Discover the Precision of Automated Tube Sealing

Highlighting essential capabilities that enhance lab efficiency

High-Speed Sealing

Seals sample tubes rapidly to support high-throughput labs

User-Friendly Interface

Intuitive controls designed for effortless operation

Sample Integrity Assurance

Ensures airtight seals to maintain specimen quality

Compatibility and Versatility

Works seamlessly with various tube sizes and types

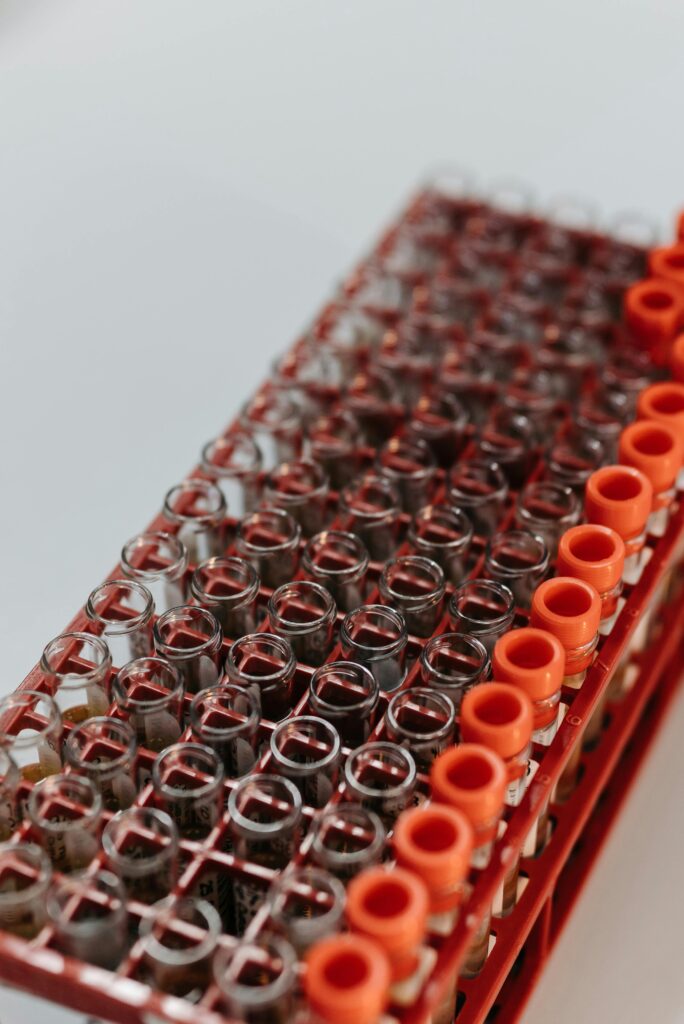

Enhancing Laboratory Efficiency and Sample Integrity

Explore how the Automated Tube Sealer tackles common lab challenges by delivering precise, reliable sealing to maintain sample quality and boost workflow productivity.

Precision Sealing for Consistent Results

Our device ensures airtight sealing of sample tubes, preventing contamination and preserving specimen integrity with unmatched accuracy.

Streamlined High-Volume Processing

Designed for busy clinical labs, the sealer accelerates tube sealing tasks, reducing manual labor and minimizing errors.

Reliable Automation for Workflow Optimization

Integrating this solution transforms sealing into a seamless, error-free process, enhancing overall laboratory productivity.

Customer Success Stories with Automated Tube Sealer

Discover our clear, step-by-step guide to efficiently using the Automated Tube Sealer for seamless lab operations.

How a Lab Boosted Efficiency with Automation

This case study details how a clinical lab improved throughput and sample integrity using RayStar HEALTH’s sealing technology.

Optimizing Laboratory Workflow with Automation

Explore how healthcare facilities enhanced productivity and reduced errors by adopting our tube sealing solution.

Sustained Laboratory Excellence through Innovation

This case study reveals how a hospital lab overcame processing delays by integrating our automated sealing system.

Subscribe for Expert Insights

Discover how subscribing connects you with cutting-edge healthcare automation solutions and expert updates.